Today you can choose from so many different types of packaging. You must choose the best packaging to attract customers and be the best in the market. Today let’s talk about a unique type of packaging style. This is the molded pulp packaging.

Molded Pulp Packaging

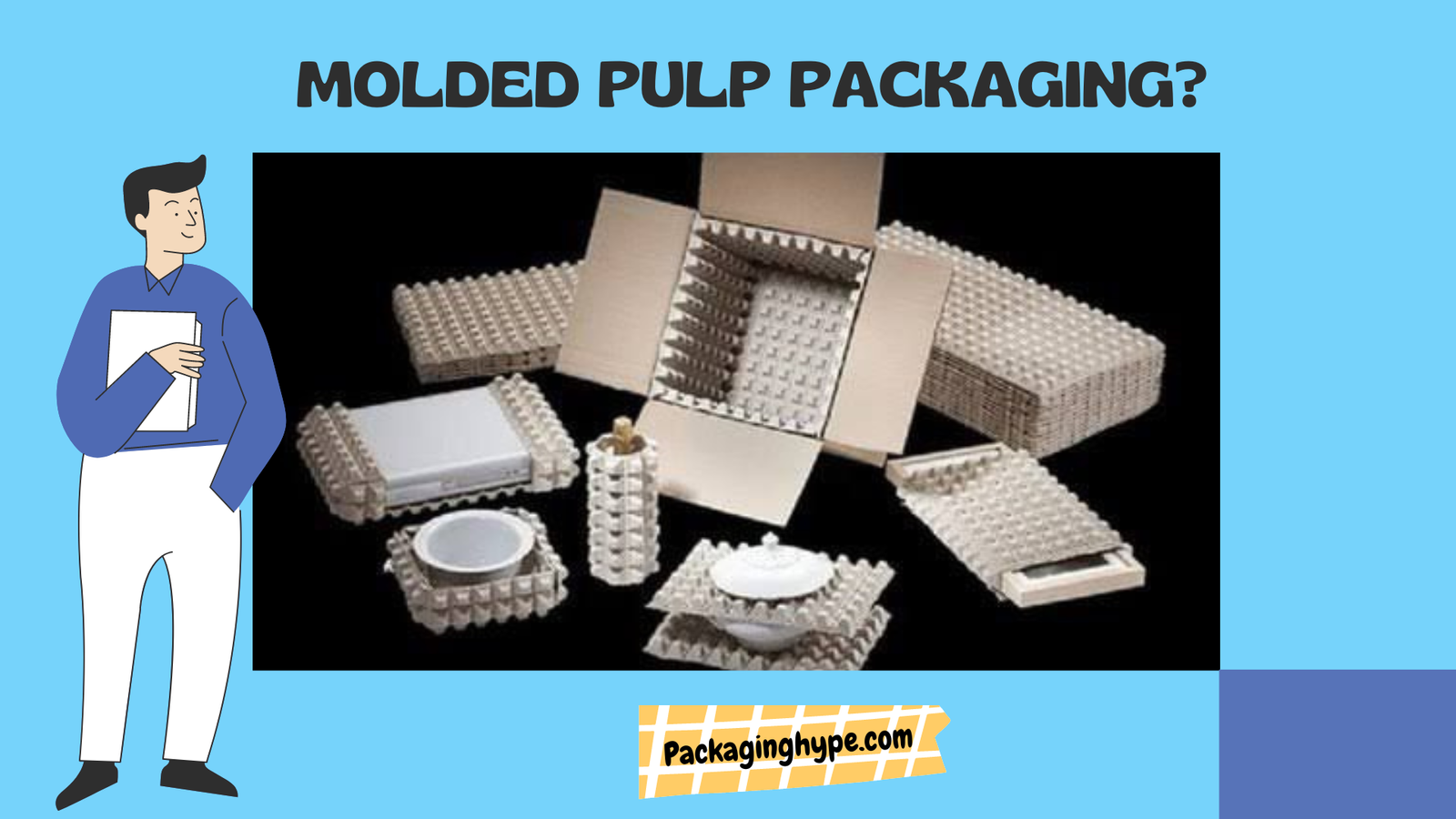

Molded pulp is recyclable, compostable, and biodegradable. It is made from a combination of water and recycled paper, mostly kraft waste from our cardboard mills, recycled newsprint, or both, shaped with a wet-press technique and heated to add strength and stiffness. The molded pulp, also known as molded fiber, the packaging is made from various fibrous materials such as recycled paper, cardboard scraps, or natural fibers, i.e., sugar cane bagasse, bamboo, and wheat straw. Raw materials help determine the package’s color, surface finish, and physical properties.

How is it Manufactured?

Molded packaging is made from recycled fibrous materials, especially natural fibers such as recycled paper and cardboard. These materials determine the package’s strength, surface finish, and color. Packages are formed from the beginning of manufacturing and do not start with flat sheets like cartons. Its design includes complex 3D shapes and rounded corners. Technological advances give the final molded pulp product a refined look, feel, and smooth surface. With these improvements, it is no longer limited to traditional packaging containing only end caps and egg cartons but is now in widespread use.

The growing importance of sustainability makes pulp packaging an attractive option. Not only are they made from recycled fibers, but they are also recyclable and reusable. If not recycled, molded pulp is biodegradable, unlike Styrofoam and plastic packaging. You can easily identify the formed pulp. You can divide the pulp into four types. These include a heavy wall made from a single mold, transfer molding made from a transfer mold and molding operation, thermoforming made from multiple heated molds, and finally, processed. This also includes proprietary or secondary treatment processes.

Why Use This Material?

The answer to this question is quite simple. Molded pulp is clean wood-based or bagasse sugarcane, a renewable and biodegradable raw material, usually made from recycled waste-based paper/cardboard or virgin paper. Although relatively new to traditional paper packaging materials, pulp’s popularity and reputation has led to the creation of large, bespoke, heavy, small, and fragile products. It is fastly becoming a sustainable packaging option. The design possibilities are endless. Our products range from end caps, trays, plates, and bowls to clamshell containers. Also, it is a reusable, recycled packaging material. Any pulpy fibrous material you may have encountered has likely served many purposes in its lifetime. Due to the pulp’s nature, all its products can be recycled at home or public recycling centers. When found in nature, it is completely degraded in almost six weeks.

Advantages of Using Molded Pulp

This packaging has many benefits. It has certain characteristics that make using it very beneficial. Here we will discuss some of its characteristics.

Protective Packaging

Technological advances have recently created sleeker packaging with smoother surfaces and a more stylish look and feel. With an improved appearance, you can use pulp packaging in various applications. Global consumer brands use molded pulp to develop elegant and distinctive retail packaging. Some phone companies have their phones feature a smooth white cellulose liner fixed in a printed rigid box. Other companies take a more organic, natural aesthetic to their smartphone cases with rounded corners, embossed graphics, and cardboard material in natural craft colors.

Biodegradable

Can molded pulp be composted? Besides reducing your carbon footprint, molded pulp packaging is highly biodegradable. At the end of its useful life, molded pulp packaging can deteriorate rapidly and collapse completely. It outperforms its plastic counterpart. This makes it a much better packaging solution. So, you don’t need to worry about disposing of it as it deteriorates quickly on its own.

No Toxins

This material is made from biodegradable and allergy-free materials and is non-toxic. Conventional packages are made from petrochemical and synthetic materials. These materials pollute the environment and can release toxic gases when exposed to heat. So, they are not good for the environment and can cause harm while this material is safe and will not pollute.

Sustainable

Plastic pollution is one of the most pressing environmental problems. There is extensive evidence that plastic pollutes waterways and wildlife and adversely affects human health. Plastic packaging is a major contributor to the global crisis, and the quest for plastic-free packaging has helped boost demand for fiber-based packaging. Also, recycling rates for plastic are very low. Paper and cardboard packages have a high recycling rate and a well-developed recycling network. According to the EPA, recycling rates for paper and paperboard have increased from 17% in 1960 to 68% in 2018. The service life of other paper and board materials. Ensuring the environment is safe is the main advantage of using it. This packaging reduces your carbon footprint by using recycled materials during manufacturing. The manufacturing process does not emit high carbon emissions. This is the best option for all the people concerned about our environment.

Improves Brand Image

Switching to the molded pulp can greatly improve your company. This will improve the perception of your business, as most people are now more interested in environmentally friendly products than before. So, this has a positive effect on your brand image. Long-term use of plastic products can damage your brand reputation as people associate your business with unsustainable products. This can help you attract more customers. Keeping the environment safe has become a top priority. If you start using this material, your brand image can improve drastically as you will also become someone who cares for the planet.

Reduction in Costs

Furthermore, molded pulp packaging is lightweight and space-saving. This can greatly reduce packaging waste and reduce overhead and shipping costs. Using this can also reduce costs because manufacturing this material requires fewer costs. This will reduce your production costs and shipping costs.

Reusable and Recyclable

You can reuse it once it reaches its end of life due to the eco-friendly materials used in its manufacturing. You can reuse the formed pulp to make other eco-friendly products for various industries.

So, all these benefits make molded pulp packaging one of the best packaging solutions!