When you think of the United Nations (UN), you picture summits, sanctions, and large gatherings that set global policy. But did you know that the UN also offers guidelines for transporting risky products and hazardous materials?

UN packaging codes are a global system of labelling established by the UN. These multi-part codes might be challenging to crack at first, but deciphering them becomes simpler after you comprehend and can discern each portion separately.

What are UN Packaging Codes?

On packaging for hazardous goods, there are strings of letters and numbers called UN packaging codes that offer details on various essential characteristics of the substances within. They serve two purposes:

- They ensure that those responsible for sending the products adhere to the rules.

- They make it simple to track and check packing codes.

Compliance is crucial when it comes to UN packaging ratings. A corporation that disregards packaging regulations or the UN grading system faces exorbitant fines. Because of this, every hazardous substance must pass obligatory packaging requirements testing conducted by a third-party organization to ensure accuracy.

UN Packaging Codes Certificate

The certificate has a few unique identifying numbers with the coding of the product maker and packaging supplier.

The UN certificate contains thorough information on the testing data for the relevant packaging, including boxes, metal, plastic, fiberboard, square-fibre drums, and IBC containers. The user is provided with these codes to print on the outside of boxes or other packaging materials.

How To Determine UN Codes?

You can simply crack the code using the following list of symbols and their meanings:

Packaging Type

- Drums/Pails

- Barrels

- Jerricans

- Boxes

- Bags

- Composite

Material

- Steel

- Aluminum

- Natural Wood

- Plywood

- Reconstituted Wood

- Fiberboard

- Plastic

- Textile

- Paper

Multiwall - Metal (other)

- Glass Stoneware or Porcelain

Category

- Closed Head

- Open Head

For example, with the help of the above guide, you can read a code as:

4D might refer to a plywood crate or box.

Classes And Divisions

The table of classes and Subdivisions is as follows:

Class 1: Explosives

| Division 1.1 | Substances and articles that have a mass explosion hazard |

| Division 1.2 | Substances and articles that have a projection hazard but not a mass explosion hazard |

| Division 1.3 | Substances and articles which have a fire hazard and either a minor blast hazard or a minor projection hazard or both, but not a mass explosion hazard |

| Division 1.4 | Substances and articles that present no significant hazard |

| Division 1.5 | Very insensitive substances that have a mass explosion hazard |

| Division 1.6 | Extremely insensitive articles that do not have a mass explosion hazard |

Class 2: Gases

| Division 2.1 | Flammable gases |

| Division 2.2 | Non-flammable, non-toxic gases |

| Division 2.3 | Toxic gases |

Class 3: Flammable liquids

| Class 4: Flammable solids; substances liable to spontaneous combustion; substances which, on contact with water, emit flammable gases |

| Division 4.1 | Flammable solids, self-reactive substances, and solid-desensitized explosives |

| Division 4.2 | Substances liable to spontaneous combustion |

| Division 4.3 | Substances that in contact with water, emit flammable gases |

Class 5: Oxidizing substances and organic peroxides

| Division 5.1 | Oxidizing substances |

| Division 5.2 | Organic peroxides |

Class 6: Toxic and infectious substances

| Division 6.1 | Toxic substances |

| Division 6.2 | Infectious substances |

| Class 7: Radioactive material |

| Class 8: Corrosive substances |

| Class 9: Miscellaneous dangerous substances and articles, including environmentally hazardous substances |

The numerical order of the classes and divisions is not that of the degree of danger.

What Are Hazardous Packaging Materials?

A hazardous material is any substance that, when carried in commerce, poses an unreasonably great danger to people’s health, safety, or property, according to the US Department of Transportation. Examples of substances include fuels, aerosols, lithium batteries, dry ice, paints, refrigerant gases, and mercury. UN-rated containers are frequently the ideal packing choice as shippers are responsible for ensuring that hazardous products are handled, stored, and transported safely.

Packaging Groups

Packing groups determine the protective packaging required for dangerous goods during transportation.

- Group I: great danger, and most protective packaging required. Some combinations of different classes of dangerous goods on the same vehicle or in the same container are forbidden if one of the goods is Group I.

- Group II: medium danger

- Group III: minor danger among regulated goods and the least protective packaging within the transportation requirement

Note: If one of the individual SDSs has a lower number of packing groups, the lower number of packing groups should be used, i.e., the most dangerous packaging group should be listed

From the above example: the packing group is II. You may also confirm that on any of their individual SDS.

How do UN Codes work?

Hazardous substance manufacturers must submit a sample of both the chemical and the container. Then, a set of standardized exams is administered to both. Depending on the chemical and packaging design, there are various tests, but the following are required:

Drop Test

- Procedure: To perform this test, the packaging must be dropped from a specific height. Finding out if the package can withstand these drops is the objective.

- Package type: In general, all packaging types pass this test, albeit some packaging types need dropping from the bottom, side, and top to obtain test results.

Leak-Proof Test

- Procedure: To inspect for leaks under stress, often from package edges or caps, the package is put under pressure using compressed gases.

- Packaging type: Any form of container used to hold liquids.

Hydrostatic Test

- Procedure: Similar to a leak-proofness test, this one checks for leaks by applying pressure with water rather than gas.

- Packaging Types: Any metal, plastic, or composite design that will hold liquids.

Stacking Test

- Procedure: This pressure test is distinct from others. Each palette may weigh up to 2,000 pounds when filled with chemicals, which makes them incredibly heavy. Consider the home products piled on pallets in bulk retail locations, where the product above the bottom layer is crushing it. A 24-hour stacking test entails piling the product’s projected shipment weight on top of the packing to ensure it won’t burst, leak, or be crushed.

- Packaging Type: All package design types are subjected to this test except for bags.

Cooperage Test

Procedure: Remove all hoops from a barrel at least two days old above the bilge (or the bulged midsection). If, after 24 hours, the diameter of the barrel does not expand by more than 10%, the packing passes the test.

Packaging Type: Only wooden barrels with bung-type closures are subjected to this test.

Vibration Test

- Procedure: Shaking the container to guarantee that vibration won’t trigger any responses is what this test entails.

- Package type: Every packaging design is subjected to this crucial examination.

Pressure Differential Test

- Procedure: The pressure differential test exposes the packaging to various pressures over time to evaluate the strength of the packaging.

- Packaging Type: The packaging intended for air travel is examined. When a plane reaches a high altitude, the pressure that makes your ears pop can also cause packages to explode.

You will be given a certification of test findings following the testing, which you may use to produce your code. This certification should be kept on hand in case of a problem with your packing.

How to Read UN Packaging Code?

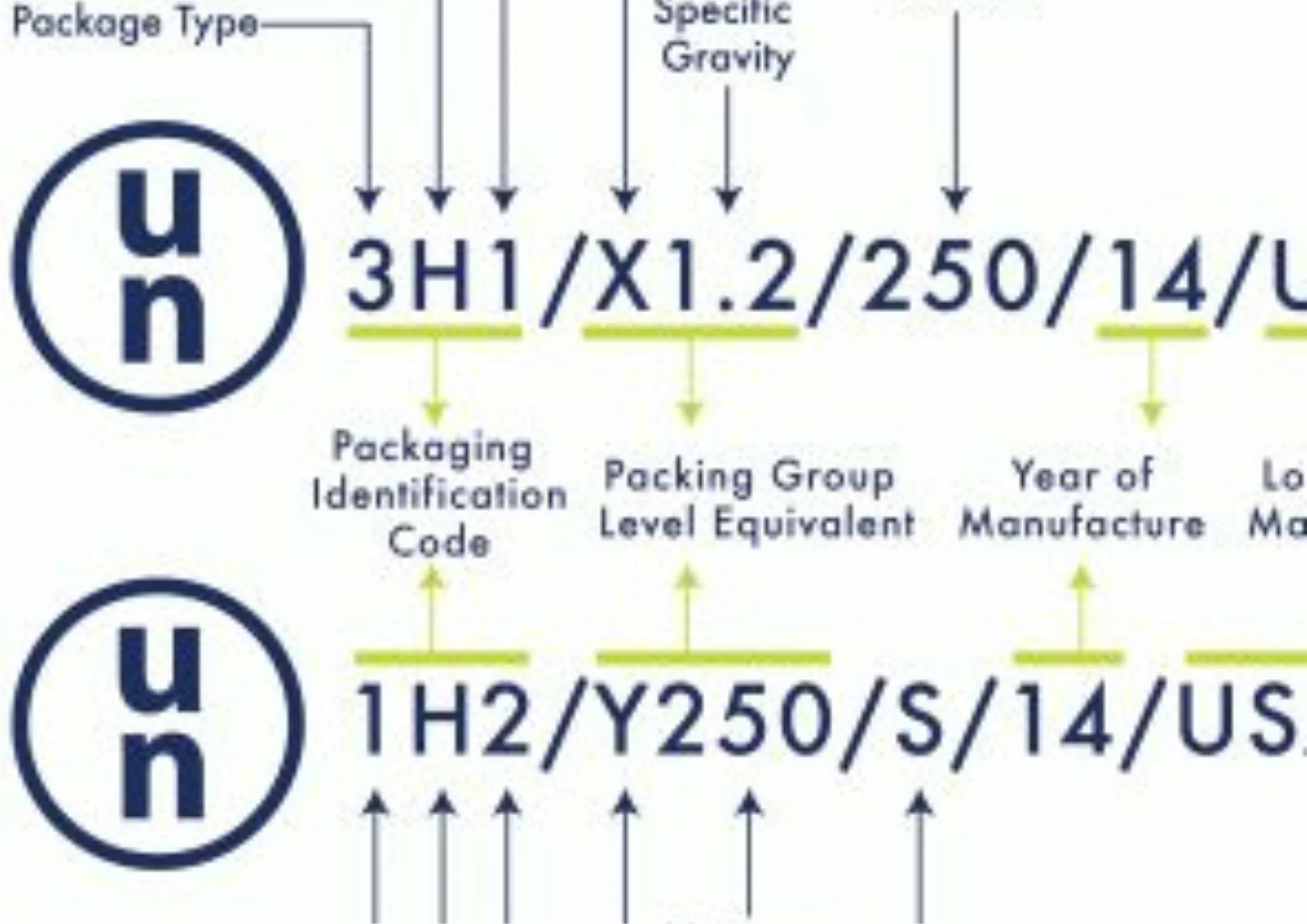

Slashes separate the six codes that make up the UN/HAZMAT insignia. Each set of codes contains crucial details that identify that particular product. Any shipment that has received UN certification and is intended to convey hazardous items must have the UN marking.

UN 1A2 / Y2.0 / 100 / 12 / USA / M4460, for instance

This steel pail is open and is UN-certified. It can securely withstand pressure up to 100 kilopascals during storage and transit. It can safely carry mid- to low-level hazardous liquids with a specific gravity of no more than 2.0.

Conclusion

With all the reasons for using UN Packaging codes, it becomes an excellent option to add a UN code to your products. It gives you reliability and approval. Your products can travel safely and securely. So, never compromise while testing your products against UN code approval tests.