Folding Cartons

If you have a company or are planning to have one. You must know the nature and the size of your product. You know why. Your product has to get into the packaging. You must know what type of carton to opt for.

There are different types of carton boxes. But it depends upon you what type you select. That is not your preference but a need that must be considered. Or else your marketing would suffer eventually. People usually confuse the two types of folding cartons. First, you need to know what type of folding carton is responsible for having what product.

1) Corrugated Folding Cartons

Corrugated folding cartons are cartons thicker than the other ones. It consists of three layers of cardboard. Two on the outer sides and the third ridged one on the inner side.

It is designed to have smaller inner air columns between these three layers, which maintains the box’s strength. The air spaces make the box stronger. This ensures the safety of the product and makes shipping easier.

2) Paperboard Folding Cartons

These cartons are single-layered paperboard cartons. These are usually designed for products that are less fragile and smaller in size. These are also known as cardstock boxes.

Now when you know the types of folding cartons, you also need to know what the folding carton style is. So, each carton has its different closing and opening styles. And every end user interacts differently with the packing box and its contents inside.

Different styles of folding cartons include:

1) Straight Tuck Box

These boxes have one main panel to which the other two top and bottom closure panels are attached. The straight tuck boxes fold in the same direction (front to back or back to front). Compact storage can cater to heavy and light products more efficiently. It has promising features like slit locks with zero assemblies needed. The best part is that printing can be done on either side to make advertising much better and more effective.

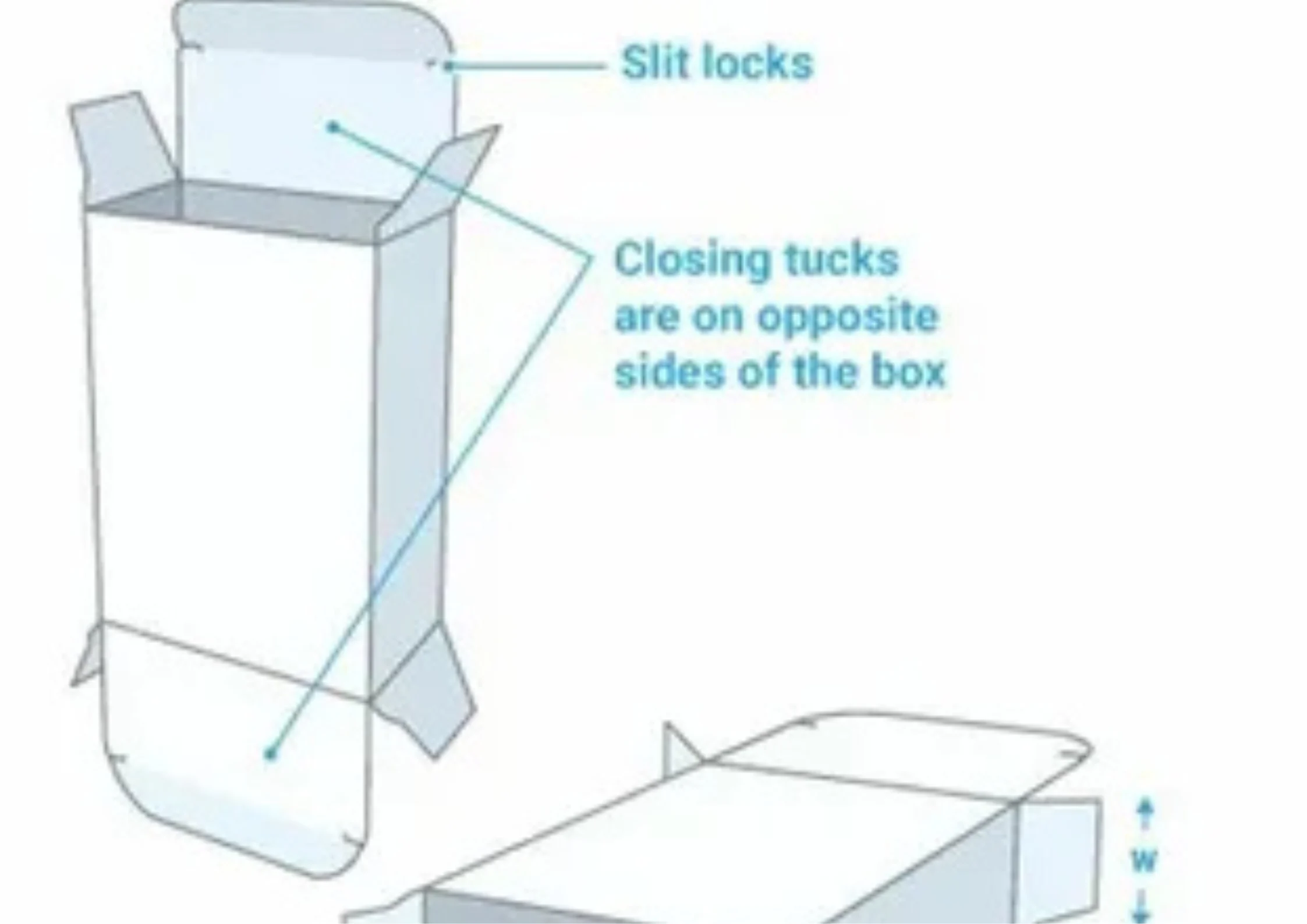

2) Reverse Tuck Box

These boxes are precisely like straight tuck boxes except for the closing panels. The closing panels are designed this way. They fold in opposite directions. They have features, all like a square soap box. These are ideal for light and heavy products. The main advantage is that the reverse box’s cost per piece is lower than the straight tuck box.

3) Lock the Bottom Box

Lock bottom boxes are also known as 1,2,3 bottom boxes. It has a top tuck panel with friction locks. These boxes are specially designed for heavier products. These can carry heavy products more efficiently. Assembling this box is relatively easy and takes very few seconds. It also gives the best of its specifications. The critical feature of this box has a flat bottom, allowing products to stack perfectly on the bottom.

4) Crash Bottom Box

The crash bottom box is also known as the auto-lock bottom box. It can be identified with the name that these boxes have auto bottom locks that give extra support to the bottom and help the product not to fall. This gives extra strength to the box. It needs no support; you must pop them up to open them. Again, the flat bottom of the box helps the box be more strengthened and carry heavier products.

5) Holster Box

These boxes are the best-designed boxes in terms of advertising. Why? Because the top part of the box is transparent or opened. The top part is not covered to make the product visible. This lets customers know what product is inside. These types of boxes are used for the soap bars. It has a straight tuck and lock bottom.

The top part of the box can be designed in any way. It doesn’t have to be designed in shape precisely like its bottom. This makes the box and the product so attractive to the customer.

6) Counter Display Boxes

The counter display boxes are somewhat like holster boxes. The common thing they both share is the visibility of the product. These are the 2 1 boxes. These are specifically designed for smaller products. The best features include holding cutouts and easy opening of the box with compact storage. The best example is shopkeepers’ pencil boxes on their counters to attract customers. This only needs them to see, grab, pay and go.

7) Five-panel Hanger Box

This is a reverse tuck box with a hanger panel extending from the back of the box. The hole in a hanger panel allows it to hang on the wall to showcase any lighter product within it. Yes, it is ideally designed for lightweight products for retail display. Having the same features as the other boxes, it has compact storage with easy assembly and holds the cutouts. Not the whole of the product, but some part of the product is visible from the box.

8) Two-piece Boxes

These boxes are also known as simplex trays because they give a display-like tray. This box has two identical pieces, but one is for the covering purpose, and the other is to hold the product. The box designed for the product is more robust as it has to carry weight. At the same time, the other one is lighter than it used to cover the product. When you remove the cover, the bottom box looks like a tray.

This box also has compact storage with more reliability of the product not falling as it has double walls. This box is perfect when gets in combination with a sleeve box. And the box, if more comprehensive, can have multiple products simultaneously.

Conclusion

There are other types as well. Now it’s up to you what feature fits best onto your product, as every box comes with outstanding and unorthodox features. Your product has to decide what box is designed for it, considering all the specifications.